Table of Contents

Lavi Beltrac – Compatible with QueuePro

We understand that our customers may already have stanchions from another manufacturer and will want to use our products with those they already have. We designed our unique Universal Belt End to allow our QueuePro brand stanchions to connect with Beltrac and other stanchion brands.

The Universal Belt End is a clever design featuring a groove to accept male receiver splines and ‘wings’ for use in female type receivers. The combination of these two features allows the QueuePro belt to be connected to any other major brand of stanchion.

In addition to our unique belt end design we shaped our receiver splines to be accept the belt ends of all major brands. The result is that QueuePro is fully compatible with Beltrac so they can be connected in both directions i.e. from QueuePro to Beltrac and from Beltrac to QueuePro.

The utility of our belt end design is just one of the value-added features built into QueuePro stanchions.

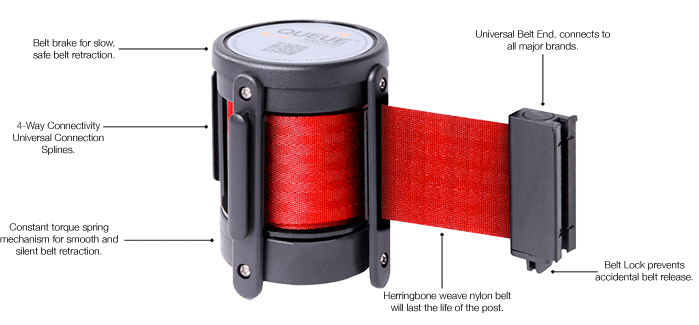

Cassette Design

The heart of a retractable stanchion is the belt cassette. This component houses the belt and its retraction mechanism. We use a constant torque spring fitted with a braking system for slow safe belt retraction. The belt end is designed with a lock to prevent accidental belt release and the belt is made of a heavy herringbone weave nylon that won’t fray or pucker for the lifetime of the stanchion.

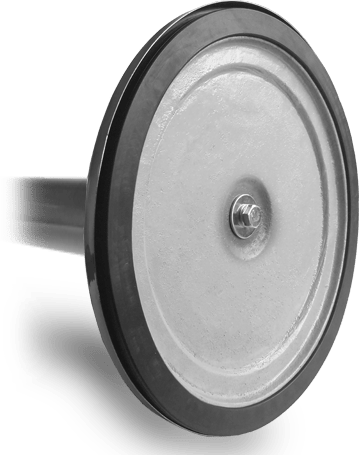

Full Circumference Floor Protector – Standard

Stanchions need heavy, cast iron bases for stability. This poses a danger to flooring as the weight means that staff are inclined to drag stanchions when moving them. Most stanchions are supplied with some form of floor protector. These are usually rubber tabs glued the underside of the base or strips positioned along the base edge. The problem with glued tabs is that over time they tend to fall off, once that happens and the base is dragged on the floor wearing off its powder coating it will rust. Rust marks are the single biggest cause of stanchion floor damage. Edge stirps are better as they have a larger contact patch and tend to last longer. However, if the protector does not go fully around the base then floor is only protected when the base is dragged on that portion of the base rim that has the protector strip.

Queue Solutions uses a full circumference floor protector on all the its stanchions. This is a heavy-duty rubber ring that is stretched around the base rim during manufacturing and cannot come off. The rubber ring protects floor no matter what angle the base is dragged and it will last the life of the stanchion.

Long Belt Lengths

The longer the belt, the fewer stanchions you need to form a given length of queue. The industry standard belt length is 7 ½ ‘, our standard belt length is 11’ almost 50% longer. That means fewer stanchion to purchase, fewer to set up and fewer to maintain. But it doesn’t end there, we have continued to develop or long length belt technology and now offer 13’ and 16’ belt options. These are ideal for large queue systems as they can halve the number of stanchions needed. Finally our latest addition to the long belt range is the 335 model stanchion. This model features a full 30’ long belt and is designed for safety applications where barriers are often set up in long straight runs.

All our stanchions and all belt lengths are fully compatible with Beltrac and other major brands. So, if you currently have Beltrac stanchions and on you next purchase you would like to opt for longer belts, then you can simply use any of our models with the brand you already have.