Table of Contents

Unlocking The Potential Of Dye Sublimation: Durability At Its Finest

Dye Sublimation, a revolutionary printing process that has reshaped the hierarchy of textile and promotional product printing. Throughout this blog, we’ll dive into the intricate workings of dye sublimation, analyzing its technology, applications, advantages, and future potentials with our stanchion belts. From its humble origins to its current standing as a leading-edge printing technique, we’ll uncover how dye sublimation printing has revolutionized numerous industries.

What Is Dye Sublimation Printing?

Dye sublimation printing is a technique that uses heat to transfer dye onto materials such as fabric, metal, ceramic, or plastic. Unlike traditional printing methods that apply ink on the surface of materials, dye sublimation involves the conversion of solid dye particles into a gas through the application of heat. This gas then penetrates the fibers of the material and solidifies upon cooling down, resulting in a vibrant, long-lasting, and fade-resistant image.

The Process Of Dye Sublimation Printing:

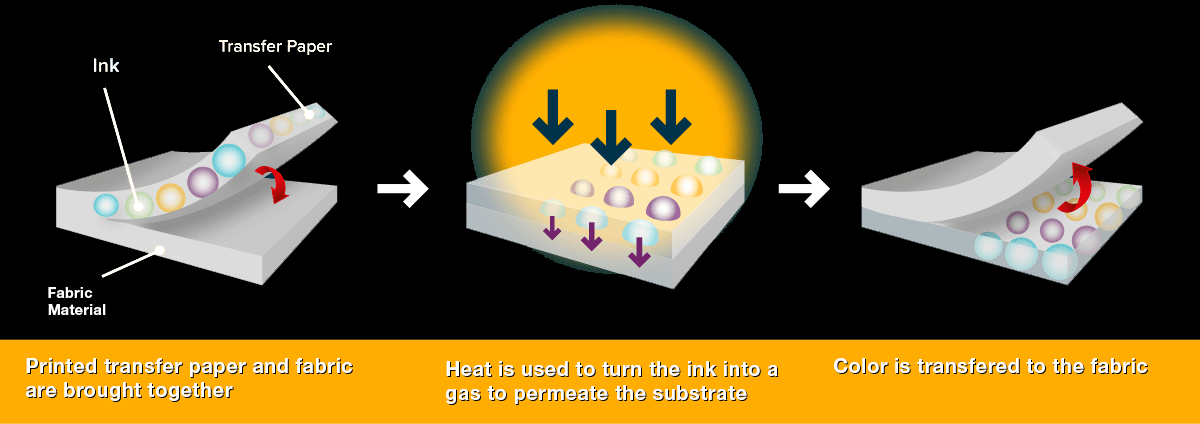

Printing:

Using a specialized printer equipped with sublimation inks, the desired image is printed onto a transfer paper which has a special coating to hold the sublimation ink for the next steps.

Heat Transfer:

The next step in dye sublimation printing is the transfer paper is placed in direct contact with the material to be printed and the two are passed through a heated roller. The heat causes the sublimation inks to transform from a solid state to a gas and permeate throughout the surface of the material resulting in a permanent bond between the ink and the material.

Cooling and Solidification:

After the heat transfer process is complete, the belt material is allowed to cool, causing the sublimated dyes to solidify, and become embedded within the material. This creates a durable, long lasting, and high quality image that is resistant to fading, scratching, and washing.

Embracing Excellence: The Advantages of Dye Sublimation

In conclusion, Dye Sublimation printing offers several advantages over the traditional printing methods for use with retractable belt stanchions. This includes the ability to produce vibrant, full-color prints with exceptional detail and resolution. Because it is a dyeing process rather than applying ink to the surface of the belt material, dye sublimation printing doesn’t crack or wear off over time as the belt is retracted and deployed from the stanchion. This feature makes dye sublimation ideal for printing the belts of retractable belt stanchions. All the stanchions we print here at Queue Solutions use dye sublimation ensuring both durability and quality.

If you want to read more blogs click Here